Official WeChat

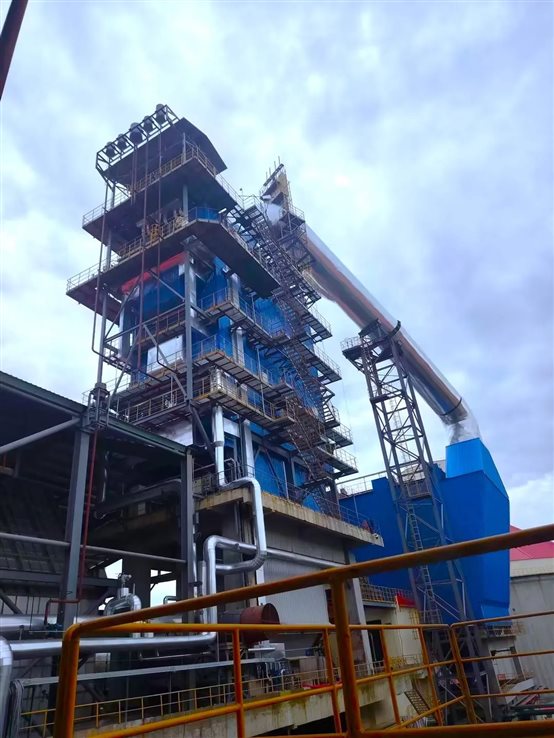

One Intelligent Digitized New Material Project Cement Production Line Waste Heat Power Generation Project Successfully Connects to Grid

Recently, the first phase of 6000t/d cement production line waste heat power generation project of Jiangshan Green Intelligent Digitalized New Material Project, general contracted by Sinoma Energy Conservation, has been successfully connected to the grid.

The project is located in the High-Tech Park of Jiangshan Economic Development Zone, Zhejiang Province, and the scope of work includes design, supply & system commissioning work. The contract was signed on May 31, 2023, the timer started on June 15, 2023, and on June 9, 2024, the unit was completed and connected to the grid for power generation.

After the signing of the contract, in order to ensure that the project generates electricity as scheduled, the project department of Sinoma Energy Conservation Engineering Subcontracting Company carefully planned the work arrangement of each stage. In the preliminary preparation stage, the project department actively coordinated with various departments to complete the basic design and procurement work in time; in the installation and commissioning stage, all the members of the project department overcame all kinds of difficulties and stood firm at the construction site, which ensured that the project reached the project nodes according to the contract as scheduled.

The project's waste heat power station has an installed capacity of 12MW, adopts the newly developed fourth generation cement waste heat power generation technology, and realizes a high degree of integration between the cement waste heat power generation system and clinker line. In the AQC system, the closed cycle of waste air is adopted, and the air cooler and chimney at the kiln head are eliminated, which effectively improves the efficiency of waste heat utilization under the premise of ensuring the clinker strength and cooling effect. The kiln tail adopts low resistance and high efficiency SP waste heat boiler, which improves the heat exchange effect and reduces the boiler resistance, and lowers the power consumption of the firing system. Electric and pneumatic valves are widely used in the power station system, and the logic control is written in accordance with the start-stop sequence of the power station, which can realize one-key start-stop and full-automatic operation of the whole power station system.

This project not only improves the economic benefits of the enterprise, but also reduces environmental pollution, improves the energy utilization rate, and makes a positive contribution to the local realization of the 'double carbon' goal.